There are millions of Vortakt barrels on rifles and pistols across the world, but you’ll never see one on the shelf in your local gun shop, or available to purchase through retailers online. Perhaps the most versatile barrel manufacturer in existence, Vortakt exclusively services the OEM (Original Equipment Manufacturer) market, selling large volumes of barrel blanks or finished barrels to rifle and pistol manufacturers across the globe. This means that there is a good chance you have at least one Vortakt barrel on one of your personally-owned firearms without even knowing it!

Company Overview: Vortakt Barrel Works

Vortakt breaks up their product offering into five different Barrel Performance Series. The barrels included in the 100–400 Series are button rifled, while the 500 Series barrels are rifled using a single-point cut rifling method.

Single-point cut rifling is a technique often used by a number of premium barrel manufacturers. This approach to rifling a barrel eliminates the possibility for any residual stresses to form within the steel after the rifling process, as is often introduced through forming operations commonly utilized with other rifling methods.

Each Series designation is designed to accommodate the unique tolerance specifications of Vortakt’s clients, requiring varying numbers of additional finishing processes. Examples of this include (but are not limited to) additional tooling changes, different feed rates, and the option to lead lap the bore.

While the concepts behind button and single-point cut rifling are well-defined, what sets Vortakt apart from the rest of the industry is the way they have optimized the barrel production process through automation technology. Their creative and innovative use of this technology reduces overhead, increases productivity, and maximizes their client’s profit potential.

It’s a very unique approach when you consider that most barrel manufacturers still operate out of old-school job shops with a mix of manual and CNC machines, each one requiring the services of a machinist or machine operator. Vortakt’s factory floor primarily features cells of three machines, one for drilling, one for reaming, and a third for rifling. A single machine operator (or in some cases an autonomous robot) can run all three of these machines simultaneously!

How Do Vortakt Barrels Compare to Other Manufacturers?

All of this is rather impressive, but does the end product stack up to the tried-and-true barrel manufacturers that we all know and love? I reached out to Chad Weister, the Division Manager of Vortakt Barrel Works, to see if I could get my hands on a Vortakt barrel to prepare this review article.

When asked which Barrel Performance Series I wanted to test, I immediately requested the single-point cut rifled 500 Series. While most PRS competitors may be familiar with names like Krieger and Bartlein across the PRS marketplace, I was curious to see how Vortakt’s finest would stack up against them on one of my precision rifle builds.

The Test Platform: Building a New Precision Rifle from the Ground Up

After reaching out to Vortakt to inquire about writing a review article showcasing one of their barrels, they pulled a 1-10 twist .30 caliber barrel blank from one of their ongoing production runs. Not only did Vortakt provide the blank for testing, but since we were local, they also offered to thread, shoulder, and chamber the blank for a Remington 700 action that was collecting dust in the back of my gun safe.

After installing and Cerakoting the barrel with the assistance of a few friends at MGS Coatings, I had a 26” .308 Win barrel ready to roll for a little preliminary field testing! While the venerable .308 Winchester may not be the latest and greatest modern precision rifle cartridge, my selection of reloading components was fairly plentiful for this project, which is more than I can say for the rapidly dwindling stockpile of 6.5mm and 6mm bullets that I’ve been hoarding for the upcoming PRS season.

The host platform is a tried-and-true bolt action design: a Short Action Remington 700 threaded for a Badger Ordnance oversized bolt knob and a Warne Mountain Tech 20MOA Picatinny Scope Base. The trigger is a Timney Elite Hunter set to a moderate pull weight of 2.5 lbs.

This action was carefully installed in one of our PRC-700SA chassis with an M81 Woodland cerakote finish, weighed down with a handful of Gravity Blocks, stabilized by an B&T Atlas bipod. Topping this build is an EoTech Vudu 5-25×56 FFP optic with an H.59 reticle. As a bit of an aside, it’s the author’s slightly biased opinion that this scope is one of the most underrepresented quality optics in the sub-$2,000 range.

First Impressions: Inspecting the Vortakt Barrel

When I initially took receipt of the barrel, the finish and machining of the exterior profile were immaculate. That said, any barrel manufacturer has the capability of producing a barrel that’s pretty on the outside. Where you see most of the variation from manufacturer to manufacturer is the internal finish!

I pulled out a bore scope and inspected the chamber and rifling from muzzle to breech, and was not surprised to find that the hand-lapped bore appeared identical to the many Krieger and Criterion barrels I had been shooting for years. Bore uniformity tolerances on a barrel of this quality is measured in the tenths (of thousandths) of an inch, so a visual inspection most likely wouldn’t provide any discernible variation without the aid of inspection tools or gauges.

While the quality of the surface finish was impressive (there were no railroad tracks, tooling marks, tears in the lands, or other uniformity issues commonly encountered in lesser quality barrels), the real proving ground would take place at the range, where I’d be testing a variety of handloads prepared for this review.

Reloading for the Vortakt Barrel: Revisiting One of my Favorite Recipes

When I first became involved in the world of PRS competition, the 6.5 Creedmoor was just starting to find its sea legs, and the competition scene was still overwhelmingly dominated by the venerable .308 Winchester. Although there are lighter recoiling and flatter shooting cartridges available to competitors these days, there’s something reassuring about the simplicity of reloading for this classic cartridge, from its utilitarian profile and solid thump to the shoulder with each press of the trigger.

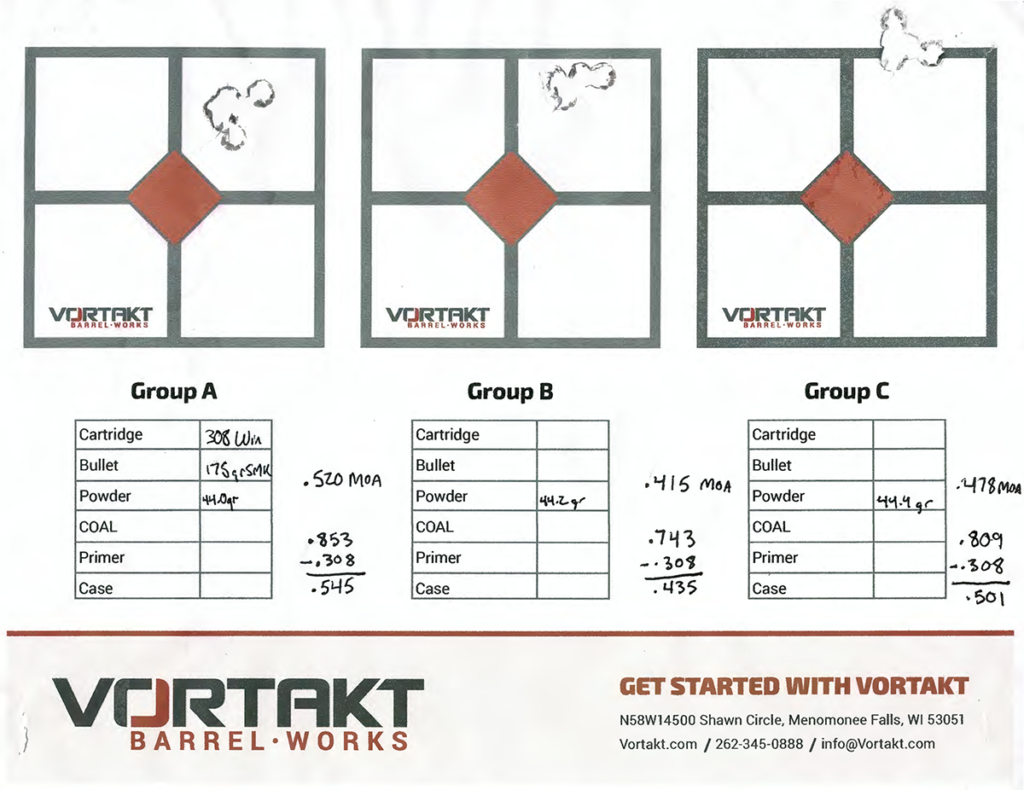

In testing this barrel, I dusted off my old favorite standby load recipe, a 175 grain Sierra MatchKing driven by 43.6-44.4 grains of Varget, seated in once-fired Lapua brass and CCI BR-4 large rifle benchrest primers. This combination has long provided me with a solid 1,000 yard-capable cartridge that has consistently produced some remarkably small groups. With a fixed cartridge overall length of 2.840”, I loaded five sets of five rounds, with each featuring adjusted powder charge rates from 43.6 to 44.4, in .2 grain increments.

In my typical load development process, I’d first try optimizing for overall length, then adjusting for charge weight, but with SHOT Show and another upcoming vacation looming on the horizon, I decided to test both variables individually to expedite the review process and incorporating all testing into a single range trip.

Accuracy Results with the Vortakt 500 Series Barrel

It’s worth noting that a true barrel accuracy test would be fired from a text fixture or benchrest setup, minimizing the potential for human error and building a rock-solid shooting platform. While some bipod shooters are capable of producing .25-.5 MOA groups from a bipod and rear bag, I’m feeling pretty lucky if I can consistently generate groups in the .5 MOA range.

With this in mind, I sought out to see if these loads would effectively match the shooter’s ability, and will work on putting together another follow-on article highlighting the barrel’s true potential once I get access to a proper test fixture.

With that very distinct asterisk in place, I set to work on putting the Vortakt barrel to work. Accuracy testing in the Wisconsin winter can prove to be a fairly arduous task. I first set to zeroing the rifle with a few rounds of Creedmoor Ammunition’s 175gr. BTHP load, very quickly finding a point of impact just outside the small diamond targets offered on Vortakt’s website.

Vortakt claims that the accuracy of their barrels generally improves after the first 25 rounds, so I decided to put that to the test. I fired 25 rounds of the Creedmoor ammunition in a series of 5 round groups, letting the barrel cool between each group (a very easy task to accomplish in 15 degree weather conditions).

By the end of that 25 round break-in period (no cleaning or break-in procedure was followed aside from simply fouling the barrel), five round group sizes had indeed shrunk from approximately .75 MOA to around .5 MOA.

Vortakt’s 500 Series barrel line is capable of sub-.5 MOA five round groups fired from a bipod and rear bag,

Field Testing Handloads with The Vortakt Barrel

With a cooled barrel and suppressor, I engaged in strings of fire of five rounds each, recording the results at the end of the session. As was indicated from my initial visual assessment, the Vortakt barrel did not fail to impress, delivering groups as small as .415 MOA! Between all five loads, the overall average five round group size came out to .524 MOA, right in line with the author’s accuracy threshold when shooting off a bipod.

Based on this initial test, I can say with a high degree of confidence that Vortakt’s 500 Series barrels are well in-line with their direct competitors in the PRS world, and look forward to evaluating this barrel further once the spring thaw kicks in, load development continues, and a dedicated benchrest rifle or test fixture is assembled for a true test of precision.